With all the functionality of the Core Series of machines but with a much larger capacity.

Available Models

| Model Name | Dimensions (mm) | Weight (kg) | X Y Z Travel (mm) | Max work piece weight (kg) | Work table size (mm) |

|---|---|---|---|---|---|

NSD Series XL Series - 1000K |

1480 x 2910 x 2200 mm | 1800 kg | 1050x600x640mm (360mm in W) | 1000 kg | 1200 x 710 mm |

Model Info: | This model makes handling big workpieces easy with its wide 1140mm x 580mm granite table.

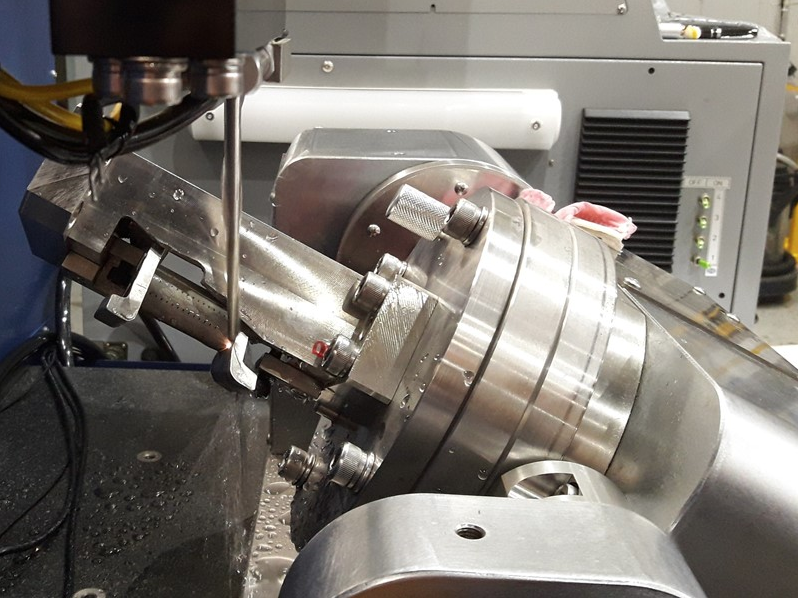

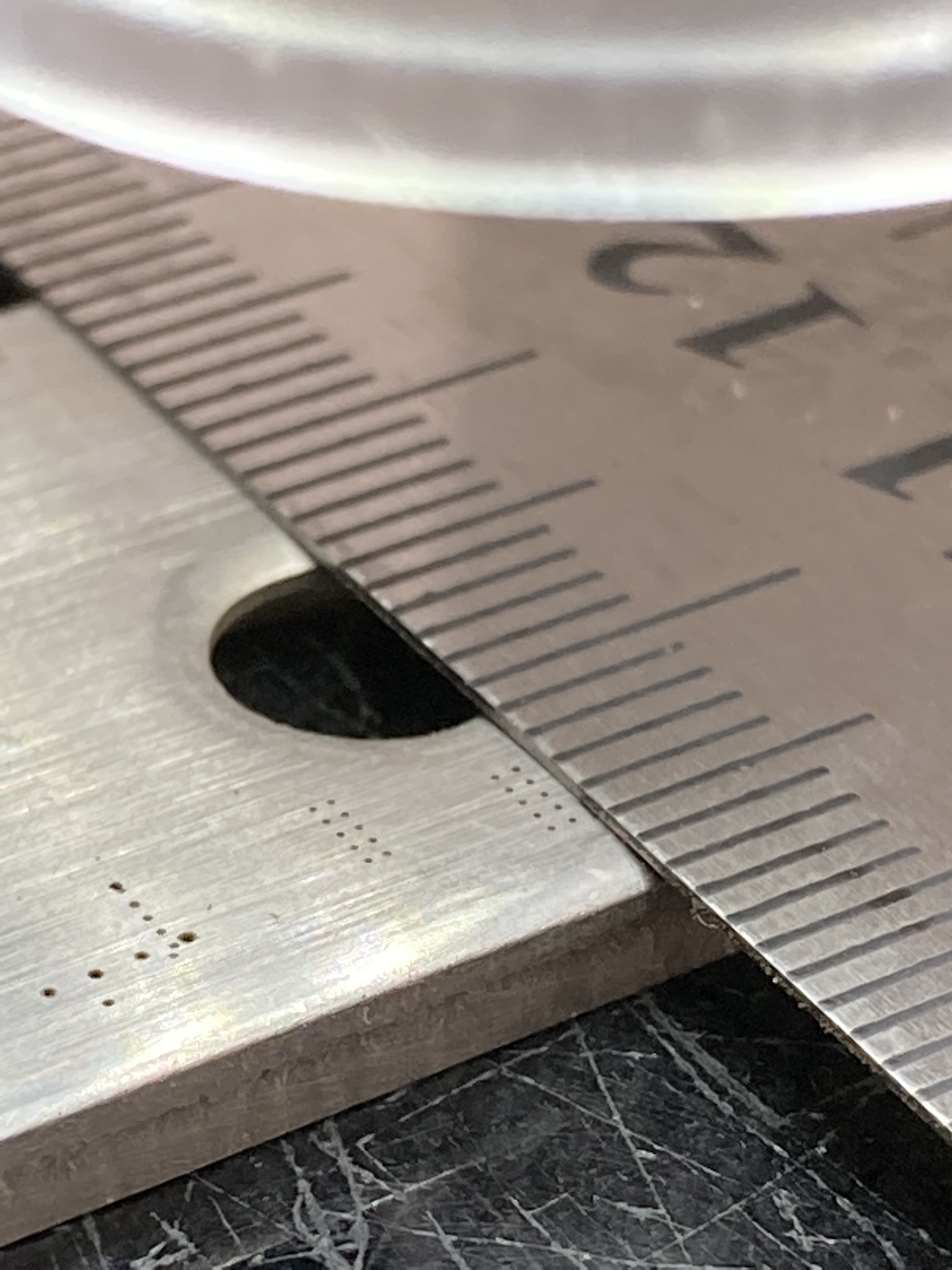

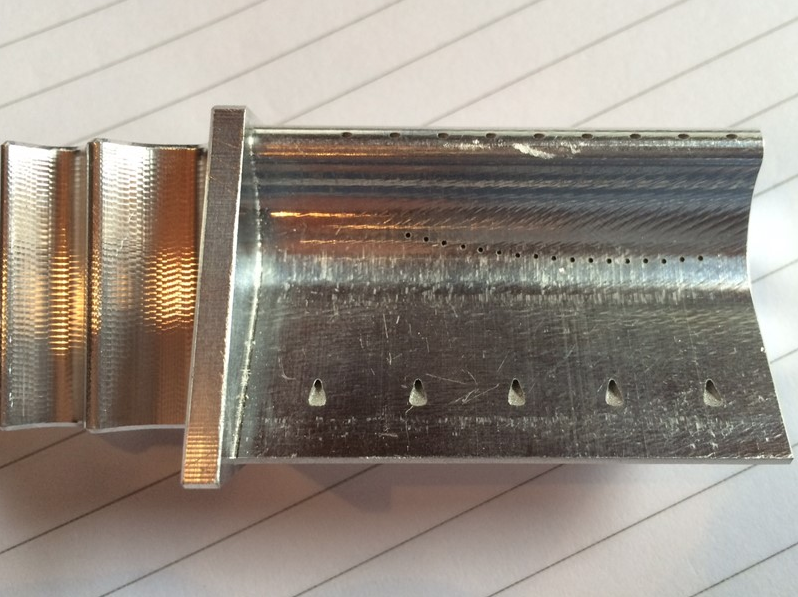

The 1000k has great with its flexibility capable of containing larger work pieces while also having enough precision for small precise parts. Features: -100% Unattended Auto Tool Changer (16 row) -Auto Thickness Verifying System, no need to wait until breaking through at the first hole. - Convenient One Touch Guide Grab/Release - Carbide inserted in the Guide hole for the better durability - Dual Moving Sub Guides for stable rotation of electrode - Small Hole Drilling (0.1 ~ 3.0mm) -Advanced CAD data Loading System Options: - Oil Machine (Use EDM Oil as dielectric) -External 60A Power Booster (Fast Drilling larger than 2.0mm) -Auto Guide Changer (allows multiple hole sizes to be drilled in one process while unattended) -EDM Tapping (Make Taps on Heat-Treated Material) | ||||

NSD Series XL Series - 8000G |

1390 x 2850 x 2140 mm | 2000 kg | 1300x800x640mm (360mm in W) | 1000 kg | 1200 x 800 mm |

Model Info: | The largest of NSD available as standard, large low open style granite table for easy loading. Features: -100% Unattended Auto Tool Changer (18 row or 14 row with Guide Changer) -Auto Thickness Verifying System, no need to wait until breaking through at the first hole. - Convenient One Touch Guide Grab/Release - Carbide inserted in the Guide hole for the better durability - Dual Moving Sub Guides for stable rotation of electrode - Small Hole Drilling (0.1 ~ 3.0mm) -Advanced CAD data Loading System Options: - Oil Machine (Use EDM Oil as dielectric) -External 60A Power Booster (Fast Drilling larger than 2.0mm) -Auto Guide Changer (allows multiple hole sizes to be drilled in one process while unattended) -EDM Tapping (Make Taps on Heat-Treated Material) | ||||